Have you ever considered the impact of [keyword] on our daily lives manufacturing cnc.

When it comes to precision manufacturing, CNC machines play a crucial role in achieving accurate and efficient results. Understanding the fundamentals of programming CNC machines is essential for anyone involved in this field. In this article, we will delve into the intricacies of CNC programming and explore the key concepts that make it an indispensable tool in precision manufacturing.

The Basics of CNC Programming

CNC stands for Computer Numerical Control, which refers to the automation of machine tools through the use of computers. CNC machines are capable of executing complex tasks with precision and repeatability. To program a CNC machine, a set of instructions known as G-code is used. G-code is a language that tells the machine how to move, position, and perform specific operations.

Understanding the fundamentals of programming CNC machines involves grasping the key components of G-code. These components include commands for movement, such as G0 for rapid positioning and G1 for linear interpolation. Other commands control spindle speed, tool changes, and coolant activation. By combining these commands, programmers can create intricate toolpaths that result in precise manufacturing processes.

Creating Toolpaths for Precision Manufacturing

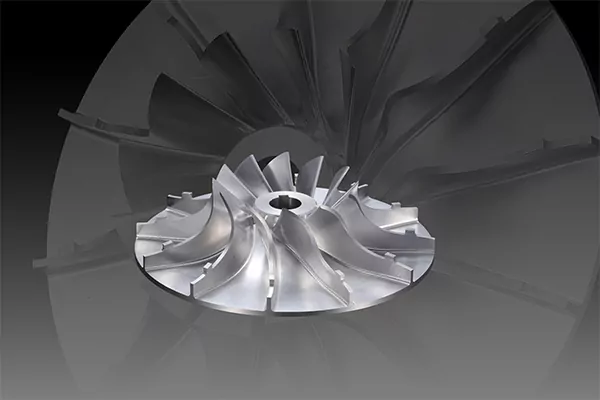

One of the primary objectives of programming CNC machines is to create toolpaths that guide the cutting tools to shape the desired workpiece. Toolpaths are a sequence of movements that determine the tool's trajectory and the material removal process. To achieve precision manufacturing, programmers must carefully plan and optimize these toolpaths.

Understanding the fundamentals of programming CNC machines involves considering factors such as cutting speed, feed rate, and tool engagement. By adjusting these parameters, programmers can optimize the toolpath to minimize machining time while ensuring the desired level of precision. For example, reducing the feed rate can result in a smoother surface finish, but it may increase the overall machining time.

Simulating and Verifying CNC Programs

Before executing a CNC program on an actual machine, it is crucial to simulate and verify the program's behavior. CNC simulation software allows programmers to visualize the toolpath and check for any potential issues or collisions. This step is essential for preventing costly mistakes and ensuring the safety of both the machine and the operator.

Understanding the fundamentals of programming CNC machines involves utilizing simulation software to identify and rectify any errors in the program. By simulating the machining process, programmers can detect issues such as tool collisions, improper toolpaths, or incorrect machining parameters. This allows them to make the necessary adjustments before running the program on the actual machine.

The Future of CNC Programming in Precision Manufacturing

As technology continues to advance, the field of CNC programming for precision manufacturing is also evolving. Automation, artificial intelligence, and machine learning are revolutionizing the way CNC machines are programmed and operated. These advancements enable faster programming, improved optimization algorithms, and enhanced decision-making capabilities.

Understanding the fundamentals of programming CNC machines for precision manufacturing means staying up-to-date with the latest technological advancements. By embracing new tools and techniques, programmers can unlock the full potential of CNC machines and push the boundaries of precision manufacturing.

In conclusion, understanding the fundamentals of programming CNC machines for precision manufacturing is essential for anyone involved in this field. By grasping the basics of CNC programming, creating optimized toolpaths, simulating and verifying programs, and staying informed about technological advancements, professionals can harness the power of CNC machines to achieve accurate and efficient results in precision manufacturing.