Maybe little things are changing the world cnc manufacturing.

From Prototyping to Mass Production: The Role of CNC Machines in Product Development is a crucial aspect of modern manufacturing. CNC (Computer Numerical Control) machines have revolutionized the way products are developed, from the initial prototyping stage to large-scale production. In this article, we will delve into the various stages of product development and explore how CNC machines play a pivotal role in each phase.

Prototyping with CNC Machines

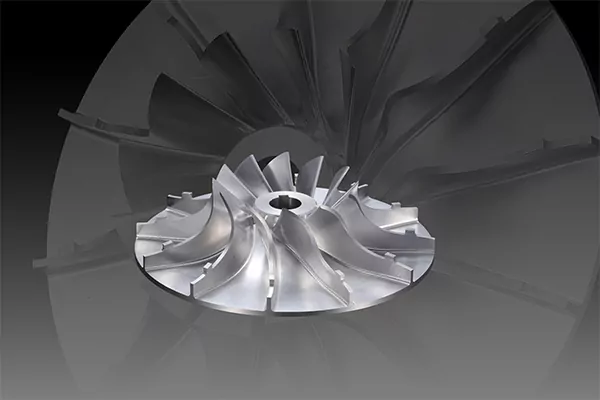

When it comes to From Prototyping to Mass Production: The Role of CNC Machines in Product Development, CNC machines offer unparalleled precision and flexibility during the prototyping stage. Whether it's creating a prototype for a new automotive part or a medical device, CNC machines can accurately produce complex shapes and designs with ease. This allows manufacturers to test and refine their product designs before moving on to mass production, saving time and resources in the process.

Customization and Flexibility

One of the key advantages of using CNC machines in From Prototyping to Mass Production: The Role of CNC Machines in Product Development is the ability to customize and modify designs with minimal effort. Unlike traditional manufacturing methods, CNC machines can quickly adapt to design changes, making it ideal for iterative prototyping and product refinement. This level of flexibility is essential in today's fast-paced market, where product innovation and customization are highly valued.

Efficiency in Mass Production

Once the prototyping stage is complete, CNC machines continue to play a crucial role in mass production. Their ability to consistently produce high-quality parts with tight tolerances makes them indispensable in various industries, including aerospace, automotive, and electronics. From machining metal components to cutting intricate patterns on wood or plastic, CNC machines offer unmatched efficiency and reliability in mass production processes.

Integration of Advanced Technologies

With the advent of Industry 4.0, CNC machines have evolved to incorporate advanced technologies such as AI (Artificial Intelligence) and IoT (Internet of Things). These advancements have further enhanced the capabilities of CNC machines in From Prototyping to Mass Production: The Role of CNC Machines in Product Development, enabling predictive maintenance, real-time monitoring, and autonomous operation. As a result, manufacturers can optimize their production processes and achieve higher levels of productivity and quality.

In conclusion, From Prototyping to Mass Production: The Role of CNC Machines in Product Development is a critical aspect of modern manufacturing. The versatility, precision, and efficiency offered by CNC machines have transformed the way products are developed and produced. As technology continues to advance, CNC machines will undoubtedly play an even more significant role in shaping the future of product development across various industries.