In today's rapidly evolving manufacturing landscape, the concept of sustainability in CNC manufacturing has gained significant traction. As the industry continues to grow, there is a pressing need to adopt eco-friendly practices and innovations to minimize environmental impact and promote long-term sustainability.

The Importance of Sustainability in CNC Manufacturing

Embracing sustainability in CNC manufacturing is crucial for reducing energy consumption, minimizing waste, and lowering the carbon footprint of production processes. By integrating eco-friendly practices and innovations, manufacturers can contribute to a healthier planet while also improving operational efficiency and cost-effectiveness.

Implementing Eco-Friendly Practices

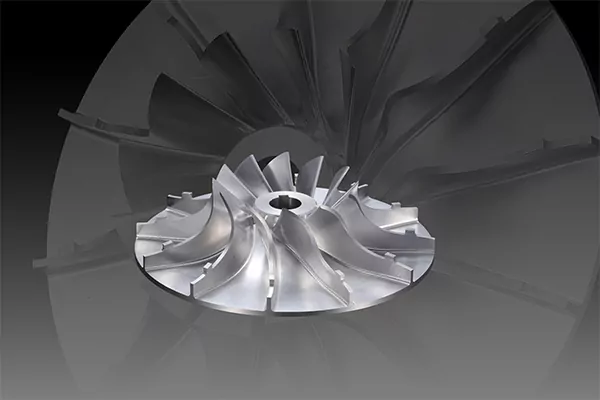

One of the key ways to embrace sustainability in CNC manufacturing is by optimizing material usage. This can be achieved through the adoption of advanced cutting techniques, such as high-speed machining and precision tooling, which minimize waste and maximize the utilization of raw materials. Additionally, the implementation of energy-efficient CNC machines and the use of sustainable cutting fluids are eco-friendly practices and innovations that can significantly reduce environmental impact.

Advancements in Sustainable Technologies

The ongoing development of sustainable technologies has revolutionized CNC manufacturing by offering innovative solutions to environmental challenges. For instance, the integration of additive manufacturing processes, such as 3D printing, has enabled the production of complex parts with minimal material waste. Furthermore, the use of biodegradable and recyclable materials in CNC machining has paved the way for eco-friendly practices and innovations that prioritize environmental stewardship.

Collaborative Efforts for a Greener Future

Embracing sustainability in CNC manufacturing requires a collective effort from manufacturers, suppliers, and policymakers. Collaborative initiatives aimed at promoting eco-friendly practices and innovations, such as the development of industry-wide sustainability standards and the sharing of best practices, are essential for driving meaningful change. By working together, the industry can achieve a more sustainable future for CNC manufacturing.

In conclusion, embracing sustainability in cnc manufacturing through the adoption of eco-friendly practices and innovations is imperative for addressing environmental concerns and ensuring the long-term viability of the industry. By implementing sustainable technologies, optimizing material usage, and fostering collaborative efforts, manufacturers can make a positive impact on the planet while also enhancing their operational efficiency. As the industry continues to evolve, the integration of eco-friendly practices and innovations will play a pivotal role in shaping the future of CNC manufacturing.